I know that this is a topic well covered in various corners of the SSS websphere, so forgive me if I am covering old ground.

I am prepping my boat (Capo 30: 30', 7500 lb displacement) for the 2017 LongPac and hopefully for the 2018 SSS Transpac. High on my long list of boat upgrades is installation of an emergency rudder system. As I see it, my options break roughly into the following:

1) Buy a complete system from a commercial fabricator

2) Work with / buy a system from a local non-commercial individual who knows what they are doing

3) Fabricate myself

4) Buy or rent a suitable system from a local sailor

For option 1), I have solicited several quotes and they have come in roughly 1/3 the entire value of my boat. This does not seem like a good fit for a poor bastard / skinflint like myself.

Option 2) is attractive, but I do not know anyone who fits this description. Suggestions welcome.

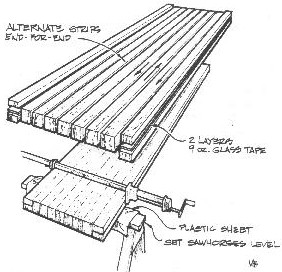

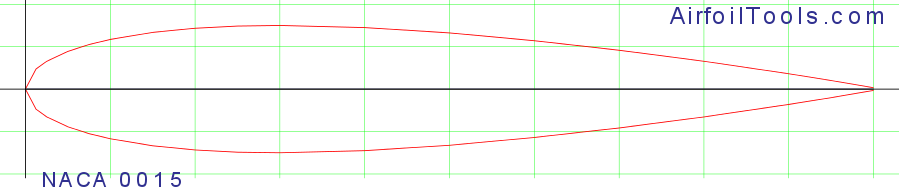

Option 3) is also attractive, but given my experience (none) in fabricating complex laminate and high-load structural materials for safety-critical systems, I frankly don't trust myself. Perhaps in combination with option 2)?

Option 4) is the most attractive of all. Surely there are boats out there similar to mine that have done the Transpac or PacCup in years past and whose emergency rudders are sitting in their garages. I would be interested in buying, or better yet renting their E-rudders (similar to renting a liferaft). They challenge is finding those boats and making contact with those skippers. Any specific leads for my boat would be welcome, along with any general ideas for facilitating the efficient re-use of the pool of E-rudders in the garages of our fellow sailors.

I am prepping my boat (Capo 30: 30', 7500 lb displacement) for the 2017 LongPac and hopefully for the 2018 SSS Transpac. High on my long list of boat upgrades is installation of an emergency rudder system. As I see it, my options break roughly into the following:

1) Buy a complete system from a commercial fabricator

2) Work with / buy a system from a local non-commercial individual who knows what they are doing

3) Fabricate myself

4) Buy or rent a suitable system from a local sailor

For option 1), I have solicited several quotes and they have come in roughly 1/3 the entire value of my boat. This does not seem like a good fit for a poor bastard / skinflint like myself.

Option 2) is attractive, but I do not know anyone who fits this description. Suggestions welcome.

Option 3) is also attractive, but given my experience (none) in fabricating complex laminate and high-load structural materials for safety-critical systems, I frankly don't trust myself. Perhaps in combination with option 2)?

Option 4) is the most attractive of all. Surely there are boats out there similar to mine that have done the Transpac or PacCup in years past and whose emergency rudders are sitting in their garages. I would be interested in buying, or better yet renting their E-rudders (similar to renting a liferaft). They challenge is finding those boats and making contact with those skippers. Any specific leads for my boat would be welcome, along with any general ideas for facilitating the efficient re-use of the pool of E-rudders in the garages of our fellow sailors.